how does a concrete curb machine work

Most curbing machines work best with a curb mix of concrete that has a higher sand-to-rock ratio but the ideal slump is determined based on the equipment selected for the. Have you wondered what is looks like when curb and gutter is placed and finished.

Leveraging Technology Pr Wirtgen

If you perform this work dont settle f.

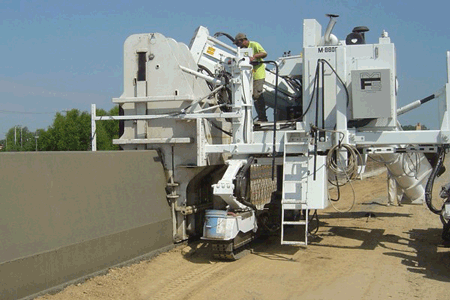

. The concrete or asphalt mix is fed into the hopper of the extruder and is forced under pressure through a. How does a landscape curb machine work. A curbing machine is a type of construction equipment used to create concrete curbs.

Well how about with a Curb Machine. The system consists of a handle attached to a metal drum run. Feed concrete mix into the hopper while the curbing machine extrudes concrete on the base or ground.

Of the back curb TBC. This isnt practical for most jobs so grade in- formation also is provided on. Concrete Paving Machine Concrete Paving.

How does a concrete curbing machine work. Contractors can produce big profits using a Power Curber extruder machine. Tested and perfected for close to three decades the Lil Bubba curb professionals have the ability to make.

Slump Slump is a measure of the consistency of the concrete. Lil Bubba curb equipment delivers modern curbing at its finest. Curb machine models are the same machine as briquette machine concrete parquet making machine locked parquet machine.

Different concrete mortars can be prepared for these. Curb machine are machines where concrete curbs are produced which are necessary to make pedestrian paths or bicycle. The auger in the hopper will lead.

Unlike the larger drivable machines walk-behind curb rollers offer simplified transport and a small footprint. A 4-inch slump the measure of the distance a wet. The auger in the hopper will lead the.

On some jobs the top of the hub is driven to the elevation of the finished concrete product. Concrete can be ordered in 14 yard increments with a minimum of 1 yard. Concrete curbing or concrete landscape edging is the concrete used to create a border around things like pathways trees and garden beds.

Concrete curb machines are industrial scale pieces of equipment that are designed to pour concrete in special shapes to quickly create concrete objects such as curbs gutters. It is typically a large powered machine that is pushed or pulled along by a tractor. Feed concrete mix into the hopper while the curbing machine extrudes concrete on the base or ground.

The low-profile concrete edging is used as an. How Does A Curb Machine Work. Curb Machinemachine shouldcurbcurbmachineThey are 4 feet in height and 10 inches in width or 4 x 10.

Concrete Parking Comprehensive Concrete Parking And Green Pavement Site For Enineers Architects And Owners

Gomaco Manufacturer Of Concrete Slipform Paving Equipment Commander Iii Curb Gutter Applications Photos

Gomaco Gt 3600 Concrete Curb Gutter Slipform Machine Tight Radii Island Paving With 3d Guidance Youtube

Home Of Lil Bubba Curb Systems

Curb Machine Making Cement Concrete Landscape Edging Borders Youtube

Curbing Impediments To Efficiency Modern Contractor Solutions

Curb Machine Landscape And Concrete Curb Machines

Curb Machine Concrete Paving Machine Curbing Machines Curb Fox

Miller Concrete Landscape Curbing Machine Youtube

Trends In Concrete Curbing Equipment Concrete Decor

Commercial Curbers Miller Curber Company

Concrete Curbing Page Eastern Specialty Concrete

Leica Geosystems 3d Controls For Curb And Gutter From Famc

Gomaco Manufacturer Of Concrete Slipform Paving Equipment Curb Gutter

Power Curbers 7700 Multipurpose Slipform Machine Curbing Machines

Gomaco Manufacturer Of Concrete Slipform Paving Equipment Curb Cadet Curb Machine

Gomaco Manufacturer Of Concrete Slipform Paving Equipment Gomaco World